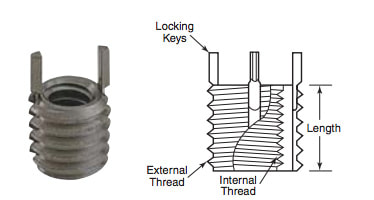

See our Keylocking Thread Inserts

Quickly repair stripped, damaged or worn out threads with a new stronger thread using keylocking inserts. Keylocking inserts are easily installed using standard drills and taps. Once the locking keys are driven down, the insert is tightly locked and will not turn. Steel inserts are C1215, parkerized. Stainless inserts are 303, passivated. Internal threads are class 2B, external threads are 2A. Inserts with internal thread size 5/16or M7 and larger have four locking keys. Smaller sizes have two locking keys. Solid inserts allow you to relocate or fill in holes that are too large. All the inserts listed are in stock for same day shipment.

Installation Data:

Step 1: Drill out hole to allow full tap depth shown in the description. Note the tap drill is oversized.

Step 2: Countersink to specifications in the chart.

Step 3: Tap hole to specifications in the chart.

Step 4: Screw in insert (by hand) to .010″ to .030″ below surface.

Step 5: Drive down locking keys with installation tool.

Step 2: Countersink to specifications in the chart.

Step 3: Tap hole to specifications in the chart.

Step 4: Screw in insert (by hand) to .010″ to .030″ below surface.

Step 5: Drive down locking keys with installation tool.

Thread Repair Tools

Quickly repairs damaged bolts. Twisting the handle opens and closes the floating blades around bolt. Rotating the tool around the bolt quickly repairs damaged threads. Adjusts to different diameters, inch or metric. Blades automatically adapt to any thread pitch, or groove. Can be used on right hand or left hand threads. Replacement blade kits available

Quickly repairs damaged bolts. Twisting the handle opens and closes the floating blades around bolt. Rotating the tool around the bolt quickly repairs damaged threads. Adjusts to different diameters, inch or metric. Blades automatically adapt to any thread pitch, or groove. Can be used on right hand or left hand threads. Replacement blade kits available